Objective

Student Furniture Holland wanted a closet that was easy and quick to assemble and disassemble by one or two persons. It should also be possible to do so multiple times without damaging the closet; something that is hard to do with for instance an IKEA closet. Students often live in small apartments that are located on the top floor. Therefore the disassembled closet had to be as small and light as possible.

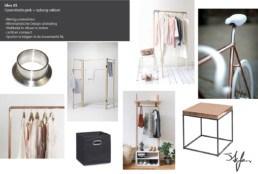

IDEA GENERATION | ARTIST IMPRESSIONS | PROOF OF CONCEPT PROTOTYPING

VALUE PROPOSITIONING | PROTOTYPING & TESTING | COST CALCULATIONS

CREATING TECHNICAL FILES

Approach

Student Furniture Holland is a small start-up. Together we decided to go through the design process in small fases with brainstorm meetings in between. Costs control is vital for a start-up and a cost calculation for each design gave them that insight. In the first fase I came up with three first concepts. Each had a sketch and a moodboard. In the brainstorm meeting one of the concepts was chosen for further development.

Prototyping + Testing

The second fase consisted of material research and the prototyping of the different technical solutions. These results were used to make an updated artist impression of the closet. A final high fidelity prototype was made that incorporated every choice we made during the brainstorm meetings.

Sourcing

One of the challenges of the project was making an affordable closet with materials found in the Netherlands. Different options for parts were presented during the second brainstorm meeting. It allowed to make choices for the final prototype that were in line with the wishes of Student Furniture Holland.

Creating Technical Files

Next to a high fidelity prototype, a set of technical drawings were made for Student Furniture Holland. It allowed them to build their own copies of the closet to keep their costs down in real start-up fashion.